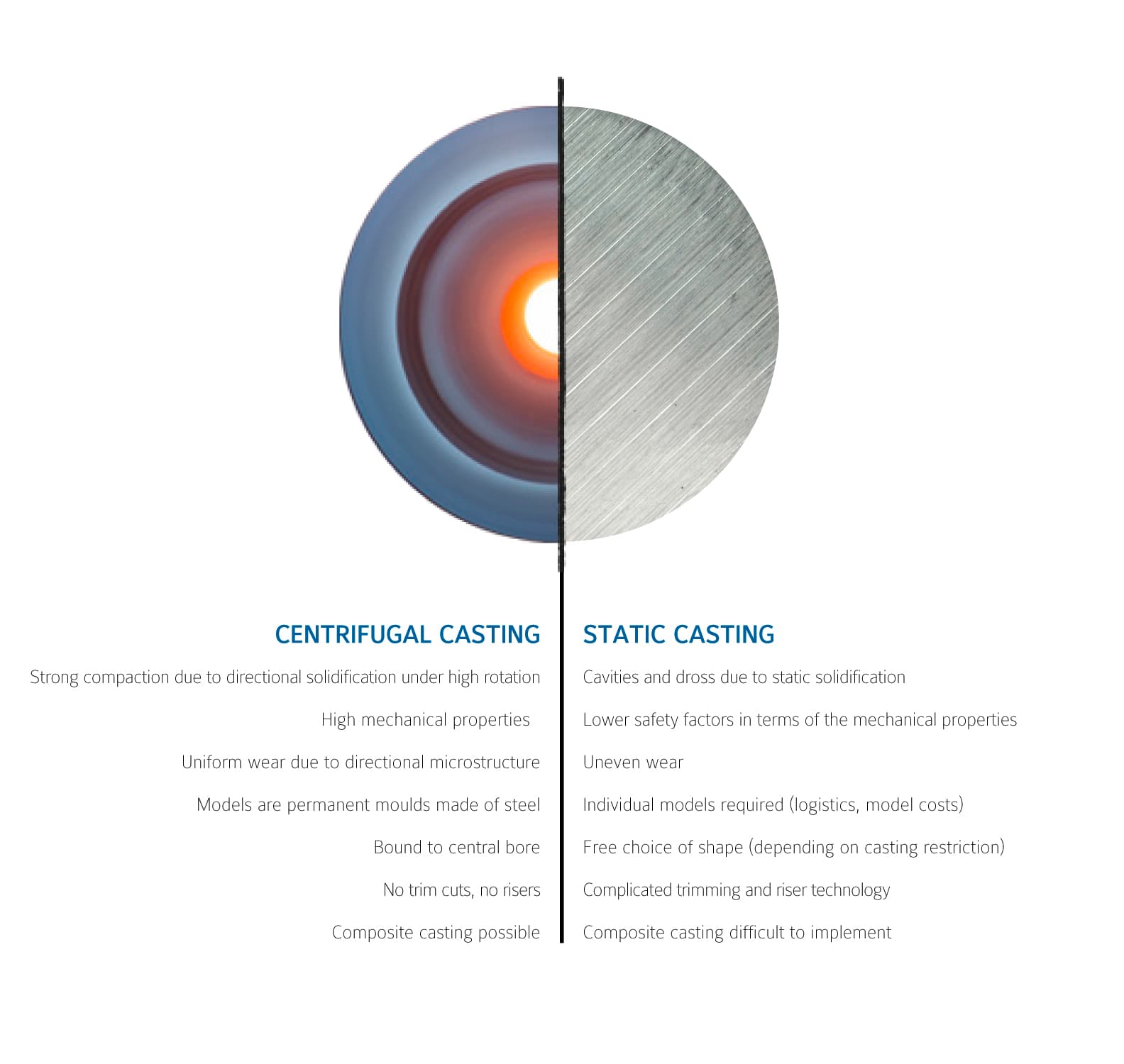

Centrifugal casting vs. Static casting

What are the advantages of the centrifugal casting process? When is it better to resort to static casting? We give you a quick overview. Continue reading

Before the differences, what do they have in common: as the name suggests, both processes produce cast products. The material used is melted and then poured into a mould. In doing so, it takes on the shape of the casting mould. However, centrifugal casting is almost always clearly superior to static casting in terms of its mechanical properties and is more comparable to the properties of forged materials. Why is that?

The main difference between the two processes lies in the solidification. In the case of static casting, the material is poured into a mould whose shape can be selected relatively freely. However, when the molten steel is poured in, cavities and impurities can occur, which are trapped in the cast product during the solidification process.

In case of the centrifugal casting process, the molten material is poured into a rotating mould, the gravity die, and solidification takes place at up to 120 times the acceleration of gravity from the outside to the inside. Thanks to the centrifugal force, coarse impurities separate much faster from the molten mass due to the density differences and are driven to the inner surface. The directional solidification also drives small porosities from the outside to the inside, creating a very pure structure with uniform properties. Impurities and pores are removed in the subsequent post-processing phase.

The downside? The biggest disadvantage lies in the geometric limitation of the method. Each component produced by centrifugal casting is bound to a rotationally symmetrical shape with a (at least small) central hole. This means: flat components such as sheets, pans, etc. as well as complex, closed shapes cannot be cast using the centrifugal casting method.

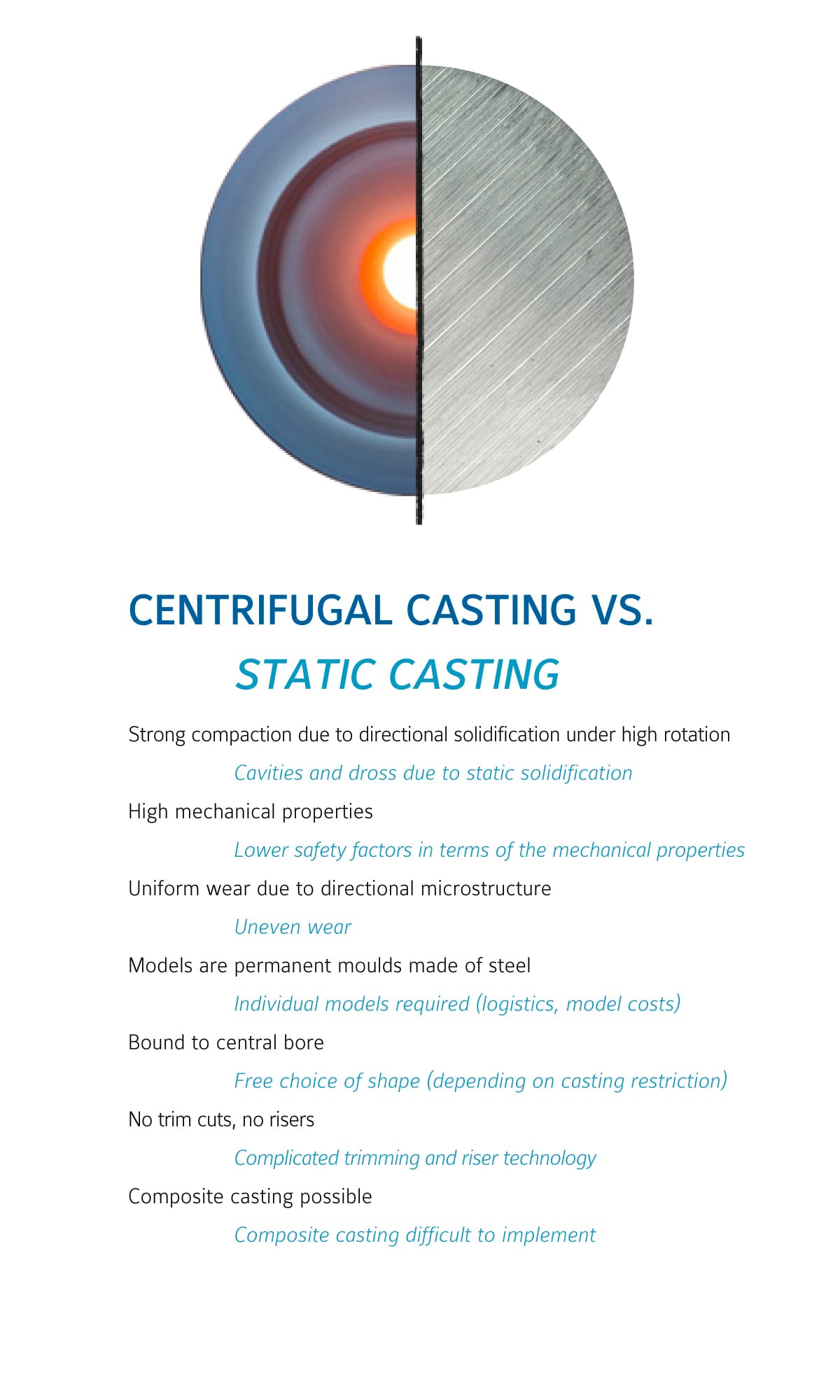

The methods in comparison: